Is it time to replace a treadbelt and deck? If the running belt does not get any kind of lubrication, It will wear out more quickly than if properly maintained. There are several ways that will show when it’s time to replace a treadbelt, a running deck or both. One way is by doing an DC Amp draw test to see how many amps the drive motor is pulling when being used at 2.5 to 3 mph. Ideally it should be between 6 and 8 Amps DC and never go above 10 Amps DC. I perform this text on most service calls. Another way is to run your hand under the walking belt where your feet land during use. If the deck has wear grooves in it your treadbelt is worn out and at this point you probably need to replace the deck as well. You may also see white fibers at the rear of the machine, underneath the deck, and around the rollers.

If you see anything like this underneath your belt and around the rollers, please stop using your machine. A problem like this would cause a lot more friction between the treadbelt and deck, causing the motor to run at higher RPM’s to keep the pace of your workout. The amperage that the motor would draw would be higher then what a motor controller could handle and sooner or later that electronic part may burn out and stop working. Motor control boards may fail when you have a treadbelt or deck issue.

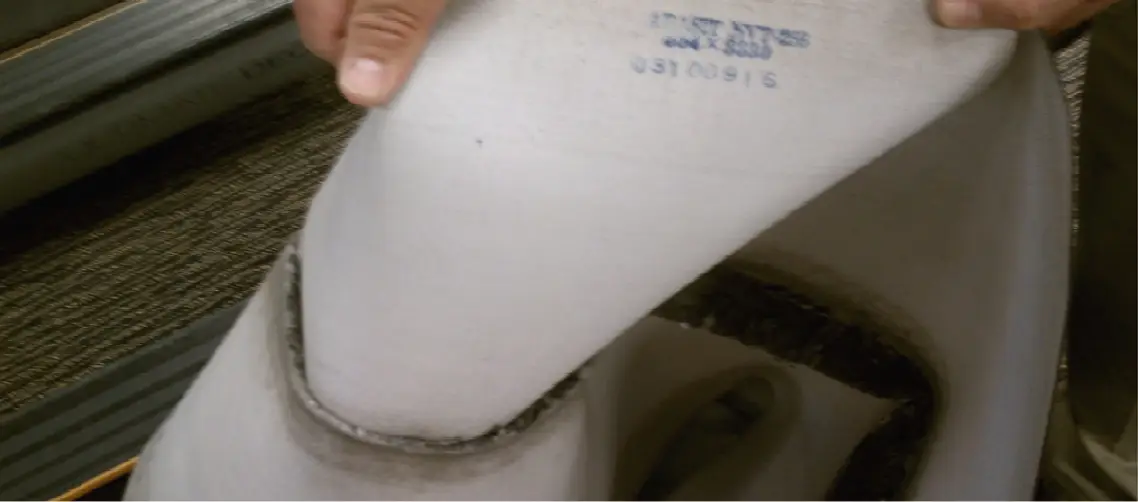

Another symptom is if the treadbelt buckles through the middle. It is a normal wear and tear in the middle of the belt since this is the area where you walk or run all the time. If you have this kind of problem you need to stop using your treadmill until replace the treadbelt:

Inspect the deck when you have an issue like this, it could be that the deck is cracked and causing this issue. If you attempt to loosen the treadbelt and reposition the belt to its normal state, the treadbelt will buckle again since the threads in the underside of the belt are not strong enough anymore. The deck should be really smooth, and should not have any type of cracks or wear grooves on the deck. If your deck has any type of grooves or cracks it may damage your treadbelt. We recommend verifying that the deck is in good condition prior to replacing the treadbelt to prevent abnormal wear or a potential issue with the motor controller or treadbelt. These are some examples of when to replace the deck. These decks have many spots that are not smooth and have random debris from dust from the treadbelt.

If the old deck on your machine has any type of damage like the example above, I recommend that you replace your deck along with your treadbelt.

Ideally a treadbelt on a treadmill that used regularly, typically should be replaced about every 3 years. A lightly used machine perhaps every 5 years. This may save ever having to replace the deck of the motor control board for the life of the machine.

Most often a worn out treadbelt looks fine on the surface. A DC Amp draw test should be performed upon an annual service.

Time to replace a running belt and deck If the running belt does not get any kind of lubrication, It may wear out more quickly than if properly maintained. There are several ways that will show when it’s time to replace a running belt, a running deck or BOTH. The most common issue is to see white dust or nylon fabric at the rear of the machine, underneath the deck, and around the rollers:

If you see anything like this underneath your belt and around the rollers, please stop using your machine. A problem like this would cause a lot more friction between the belt and deck, causing the motor to run at higher RPM’s to keep the pace of your workout. The amperage that the motor would draw would be higher then what a motor controller could handle and sooner or later that electronic part may burn and stop working. Orthopedic belts are heavier than a normal belt so it will require more power and torque from the motor to move it. Controllers may to fail when you have a belt or running deck issue. The running belt could rip and split in half if you keep using the machine:

Another symptom is if the running belt buckles through the middle. It is a normal wear and tear in the middle of the belt since this is the area where you walk or run all the time. If you have this kind of problem you need to replace your running belt:

We need to be careful and inspect the running belt when you have an issue like this, it could be that the running deck is cracked and causing this issue. If you attempt to loosen the running belt and reposition the belt to its normal state, the belt will buckle again since the threads in the underside of the belt are not strong enough anymore. A normal running deck should be really smooth, and should not have any type cracks or chips around the deck, especially the top because there is a constant friction between the belt and deck while in use. If your deck has any type of chips, marks or cracks it may damage your running belt and there is no solution to fix a deck like that. We recommend verifying that the old deck is in good condition prior to replacing the running belt to prevent abnormal wear or a potential issue with the motor controller. These are some examples of when to replace a running deck, these decks have many spots that are not smooth and have random debris from dust or the running belt:

If the old deck on your machine has any type of lines like the example above, we recommend that you replace your deck along with your running belt for better performance. It the running belt has any lines like the picture above, a new running belt needs to be installed. These lines could seem harmless but they may cause more friction with the running belt and may burn the motor controller. If the running belt was recently replaced and the motor controller failed after you inspected the deck and there was no visible damage it could also be a bad deck. The best way to determine if a new deck is needed would be by running an amp draw with a Volt meter. At this point, we suggest that a professional certified technician would perform the test to determine if a deck is needed.

![]()

Maine Treadmill Repair