[Disclaimer: As an Amazon Associate, I earn from qualifying purchases.]

I cannot stress strongly enough: The single MOST IMPORTANT ongoing maintenance routine that you, the treadmill owner, must do is to LUBE YOUR TREADBELT AND DECK REGULARLY,

This will prevent premature treadbelt and deck wear as well as avoid the possibility of the motor control board from being damaged and needing to be replaced, and the potential of other repair-related issues.

For most treadmills, 100% silicone oil is used. When a treadbelt is new, the underside has an absorbent fabric weave pattern that holds the silicone oil, keeping the treadbelt and deck lubricated. This provides two functions. It keeps the belt and deck from wearing out so quickly, as well as puts less stress on the motor and motor controller due to less friction.

For regular ongoing maintenance, I recommend applying approximately an ounce of silicone oil directly to the entire deck. If it hasn’t been lubricated in a while or if the deck feels completely dry, I would recommend applying two ounces.

For heavily used residential treadmills, I recommend lubricating the treadbelt and deck quarterly. For lightly used treadmills, or those used only during winter months, I recommend lubricating the treadbelt and deck at a minimum, annually. I can perform this annually as part of the recommended annual service.

One of the services that I perform on an annual service call is a DC Amp Draw Test. This allows me to determine if the treadbelt and or/deck are worn out and need to be replaced to prevent damage to the motor controller and other components.

Once the treadbelt fabric is worn out underneath, it will no longer hold silicone oil. In addition, the now smooth surface under the treadbelt acts like a windshield wiper, wiping any applied silicone oil to the sides under the pressure of foot traffic. Thus, the friction and DC Amp Draw will be instantly as though no lubricant was ever applied at all.

Once the fabric on the underside of the treadbelt has worn off enough, the more rigid PVC part of the belt begins to wear the deck, causing wear grooves in the treadmill deck surface.

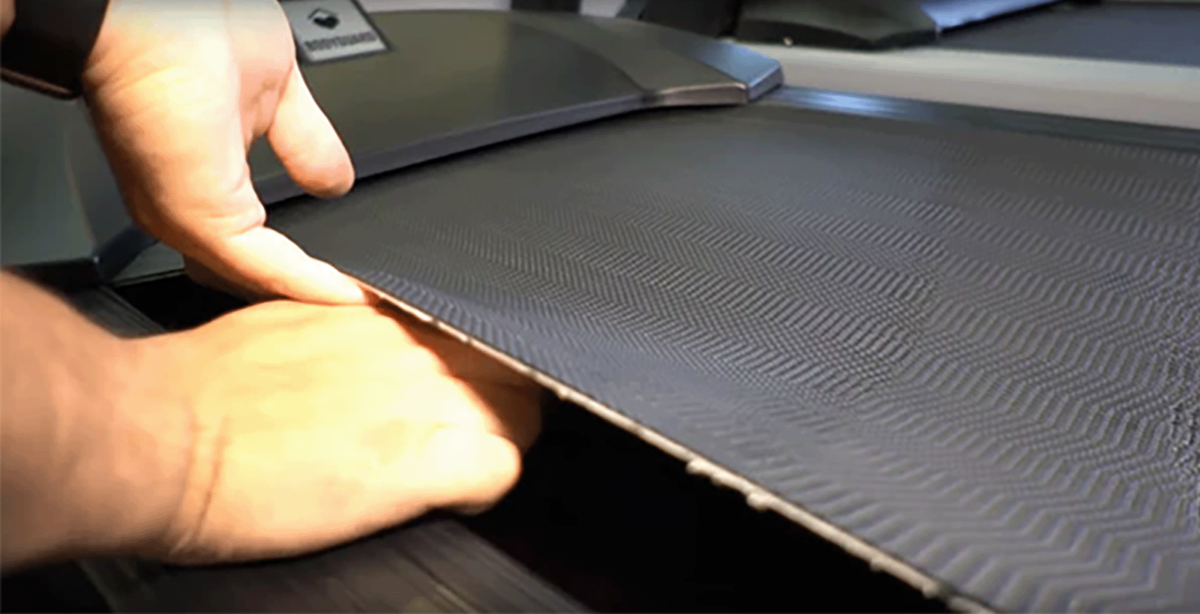

When this begins to happen, you may need to replace the deck as well. You can feel this by sliding your hand under the tread belt in the area where your feet land. Typically, when the belt is worn out, you will begin to feel these grooves on the deck surface.

I think it’s a good idea to replace the tread belt every three years on treadmills that are well-used. For treadmills that are not used frequently, you may be able to get by with replacing the treadbelt every five years.

![]()